Operating Principle Of Packaging Machine

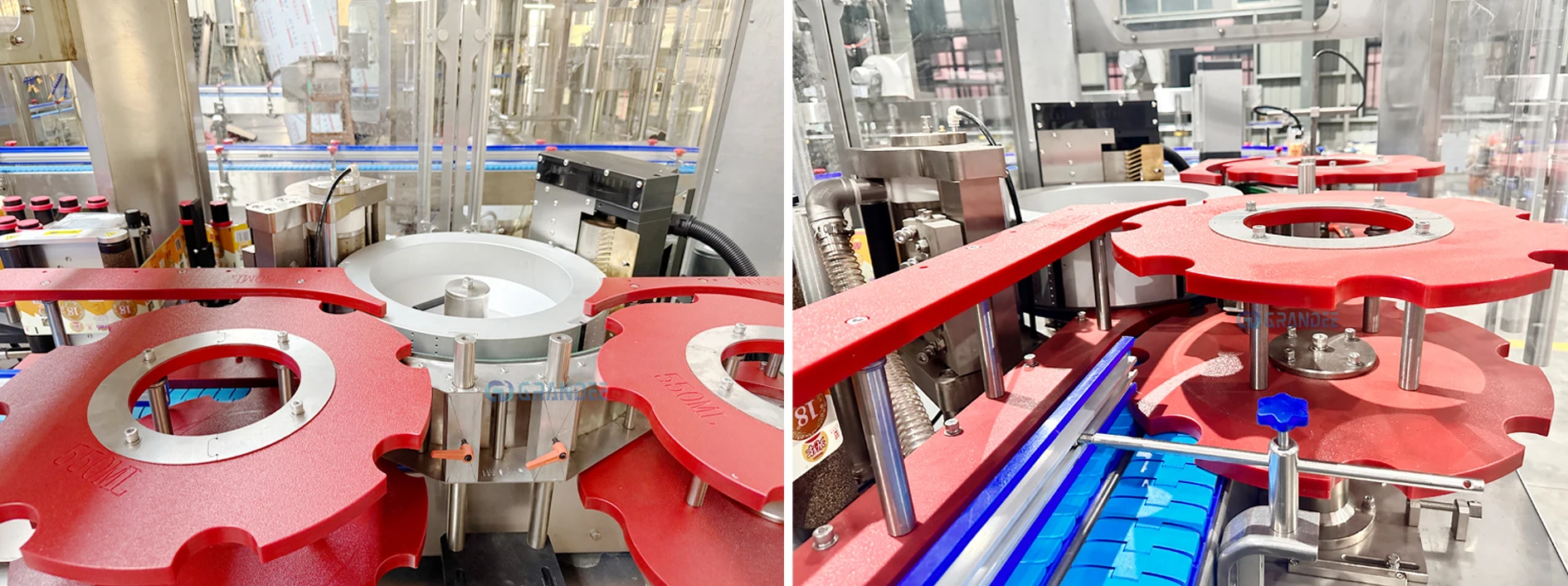

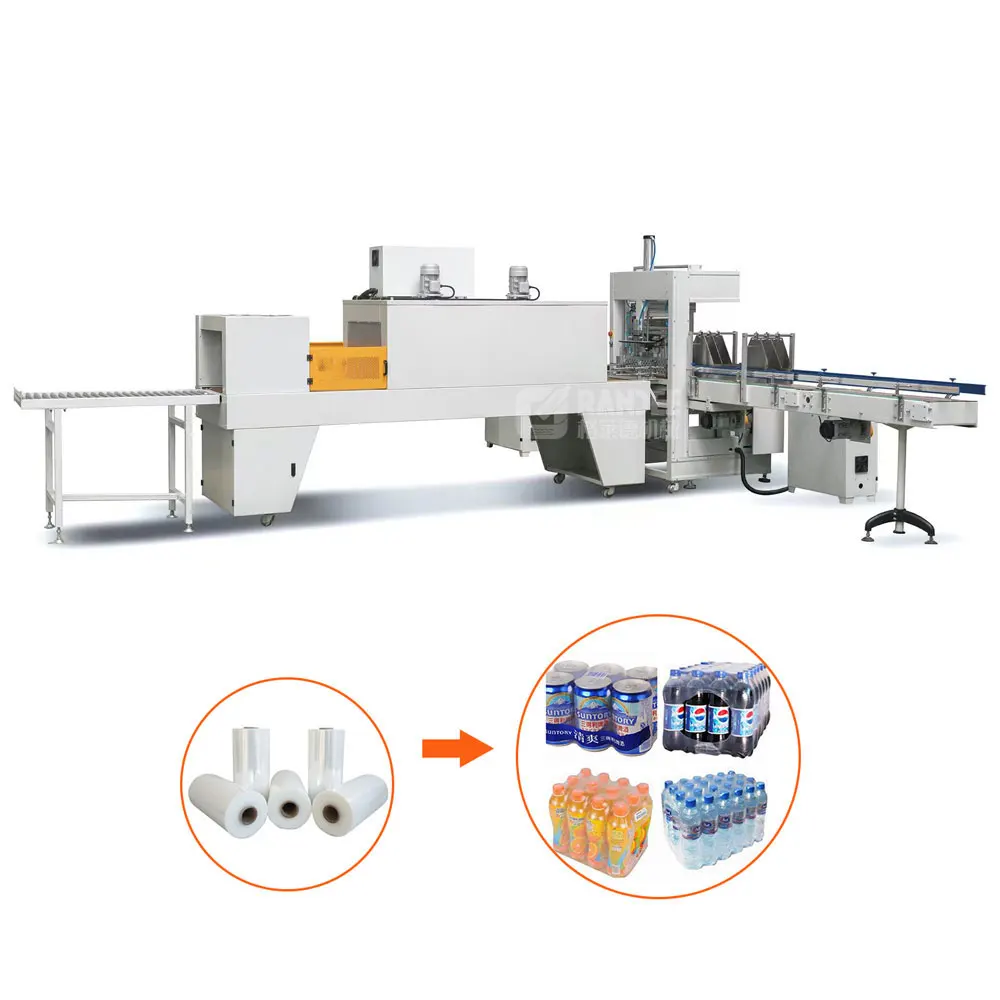

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed by mechanisms such as bottle, putting bottle, continuous pushing rod and bottle, single film wrapping, film picking and forming, heating channel shrinking and cooling and shaping.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM