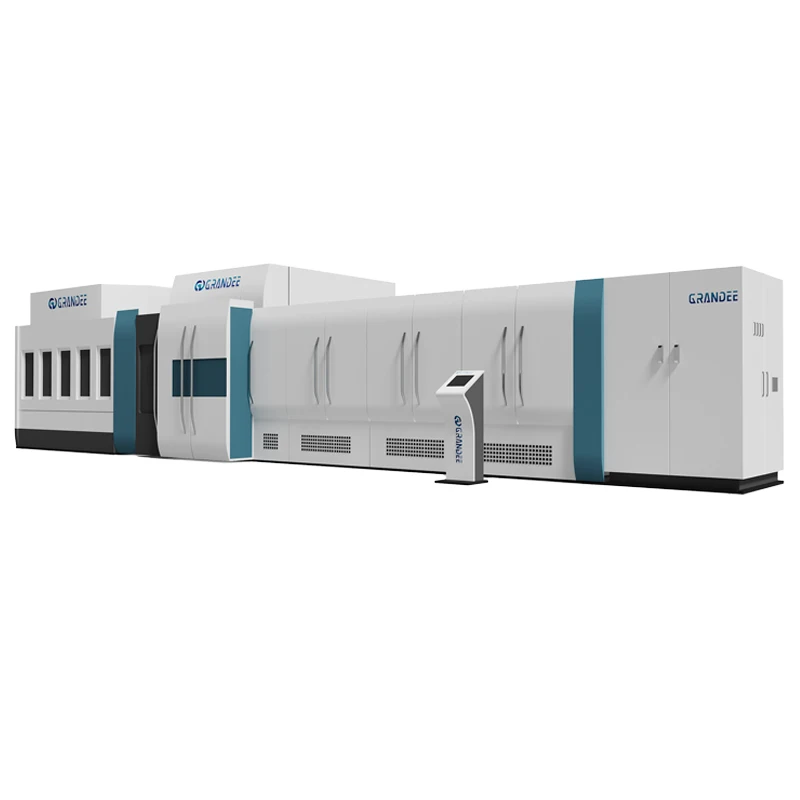

1. This can filling machine is suitable for filling beer and carbonated beverages. 2. The machine's driving force originates from the can sealer, equipped with variable frequency control for operators to adjust production speed.

3. All filling components can be lowered onto the cans, eliminating the need for can-lifting mechanisms; Cans remain on a single horizontal plane throughout the filling process without vertical movement.

4. Automatic shutdown features: Stops when inlet has cans but no lids; Stops when lid supply is insufficient.

5. Machine cannot start unless hand wheel positioning is confirmed.

6. Automatic shutdown triggered by can jams at the exit star wheel.

7. A proximity switch sensor on the in feed conveyor: Reduces machine speed and initiates shutdown when can supply is low; Gradually restores speed when can supply replenishes.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM