If you enjoy drinking fruit juice, you may have wondered how it makes its way into those bottles in the store. A fruit juice filling machine is a machine that can easily put juice into bottles. GRANDEE MACHINE, makes these machines that fill and cap hundreds of bottles in a matter of minutes! And this is a critical step in preparing your favourite juice for purchase.

Long ago, each bottle had to be filled and capped by hand. It was a long and laborious process. When filling bottles, workers would pour juices in one by one and close the cap, but at times, the juice could come into contact with dirty hands or possibly contaminated surfaces in the factory. This meant the juice could be unsafe to drink. Now, we can do all of this much quicker with our machines, and keep everything clean and safe for you.

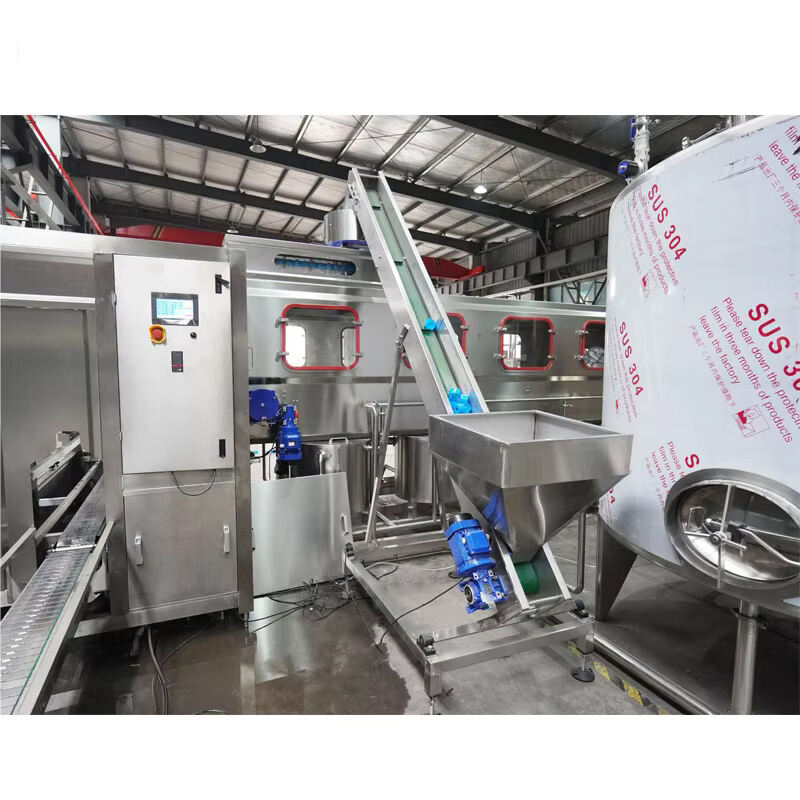

The conveyor belt is used to transport fruit juice to a bottle. It is a long, moving belt that brings empty bottles to the filling station. After the bottles are properly positioned, a nozzle pumps in the juice. This nozzle ensures only the correct volume of juice fills each bottle. Then a cap is tightly affixed allowing the juice to stay fresh and delicious. It makes this entire process fast and seamless!

To achieve this, we make use of sensors that monitor crucial parameters such as the pH level and sugar content of the juice. And these sensors are remarkable, because they tell us how the juice is processed, so that we are able to modify the filling and capping stage accordingly. Now you know that no matter what, every bottle will have that delicious taste. You can be sure that every bottle you purchase will taste the same as the previous one!

Our machines are capable of filling and capping many bottles in a fraction of the time. After they are filled, we can easily package them and send them out to the store to be purchased. So, you get the taste of freshly squeezed fruit juice without waiting for long for it to be done. We strive to get your juice to you as quickly as we can so that you can start enjoying it!

This includes servo motors that we use to control the conveyor belt and the filling nozzle. These motors are very precise which means that they can move exactly when we want them to. We also have touchscreens that help us watch the whole bottling process. Anything which needs to be changed or adjusted can be done easily. This allows for ease of use on our machines, as well as ensuring that they are in optimal working condition.

For example, we can design your filling nozzle size and shape according to the bottles you use. It can also be adjusted for your production line to adjust the speed of the conveyor belt and adjust the type of cap used. This way you can acquire precisely what you want in order to make your fruit juice bottling process as useful and viable as could reasonably be expected.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.