Key Benefits for You :

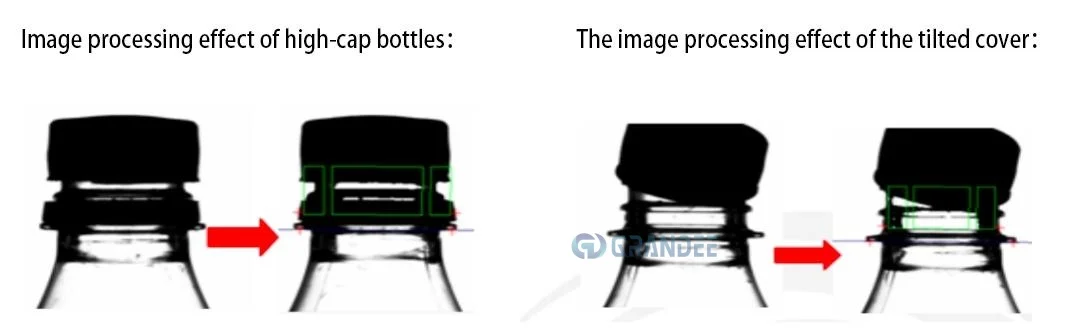

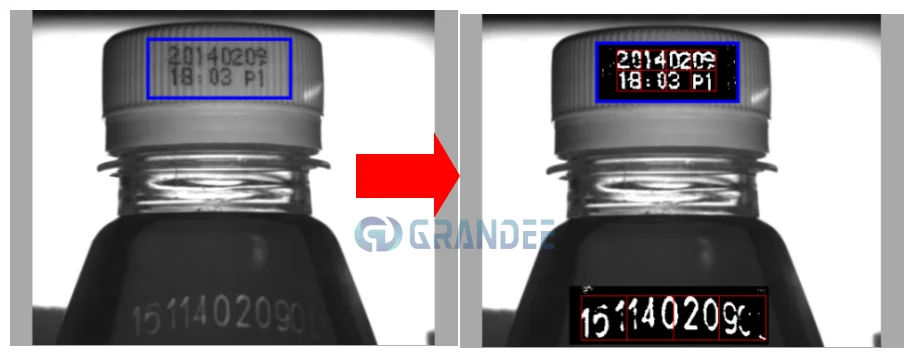

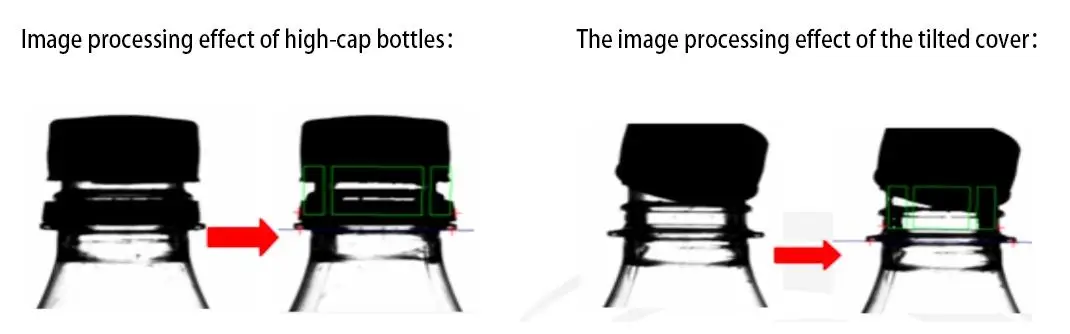

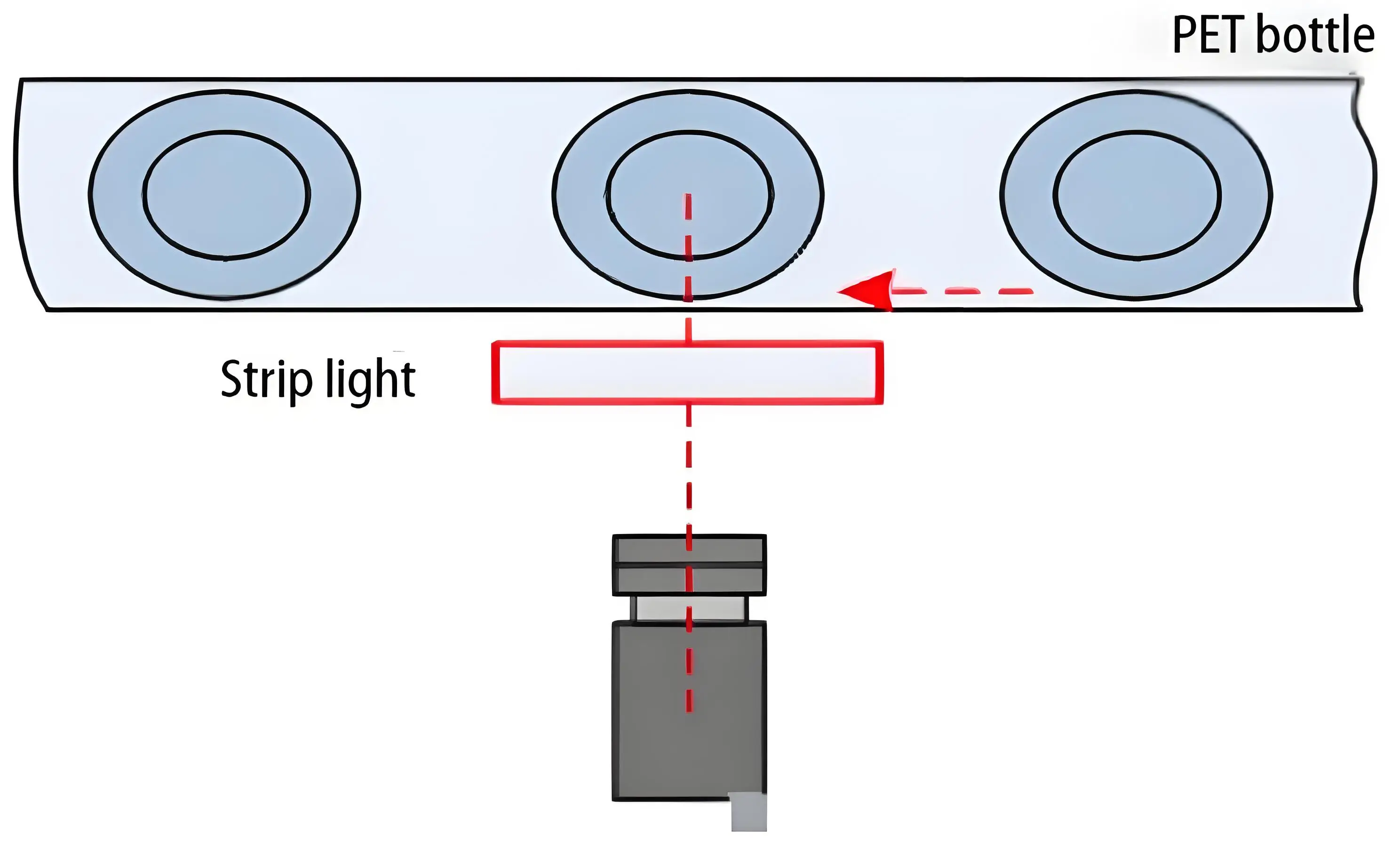

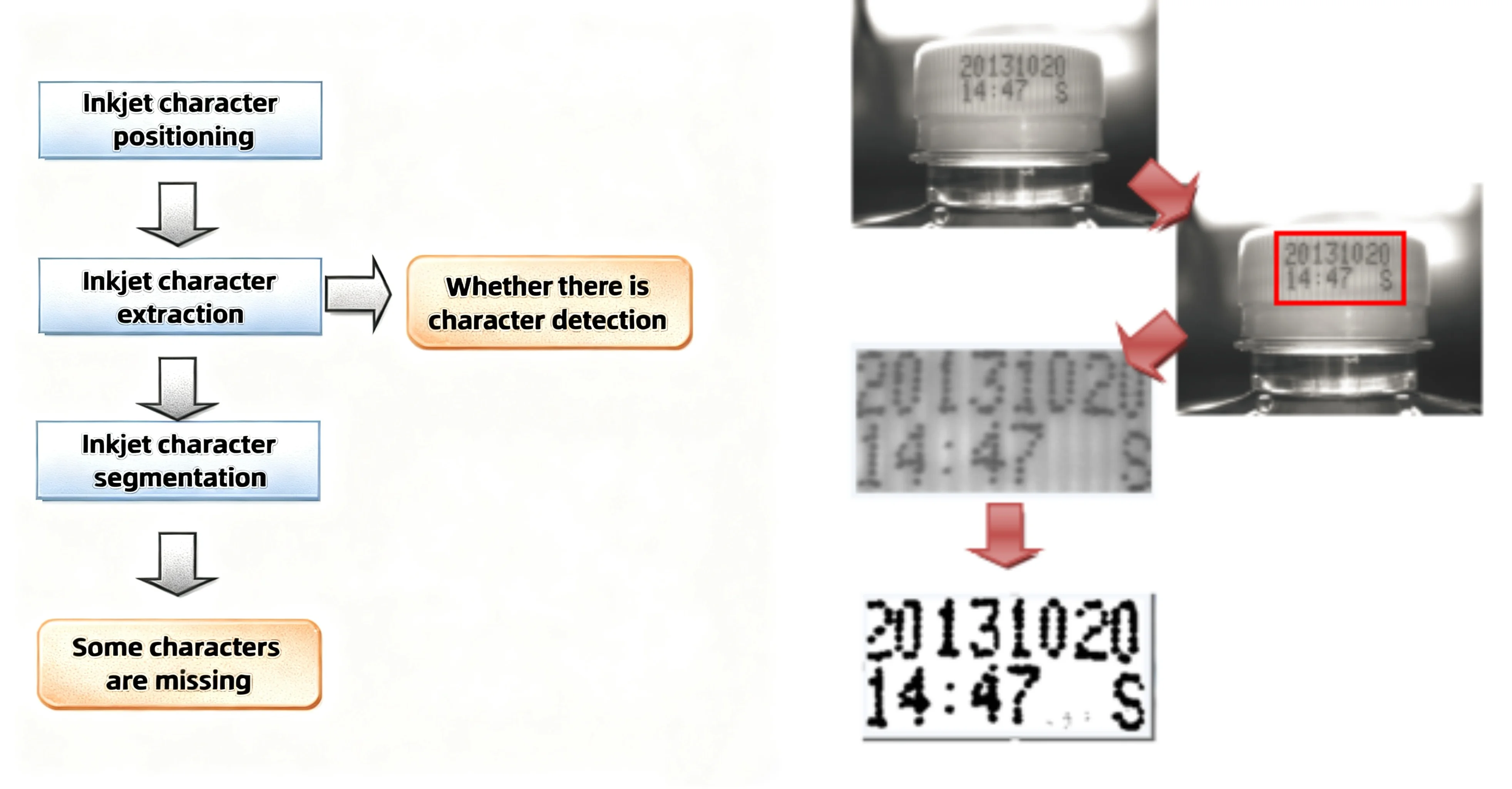

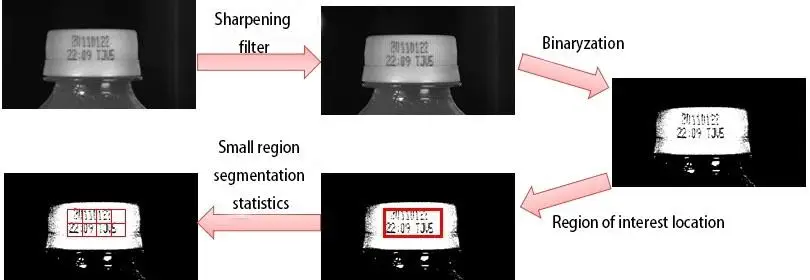

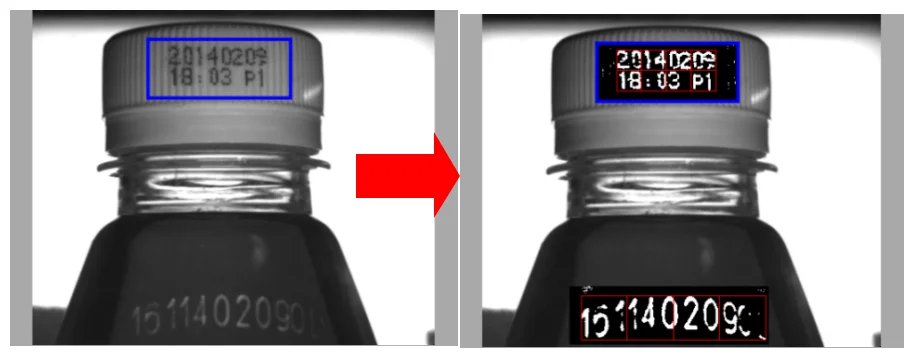

✓ 360° Inspection - Ensures no defective products leave your line.

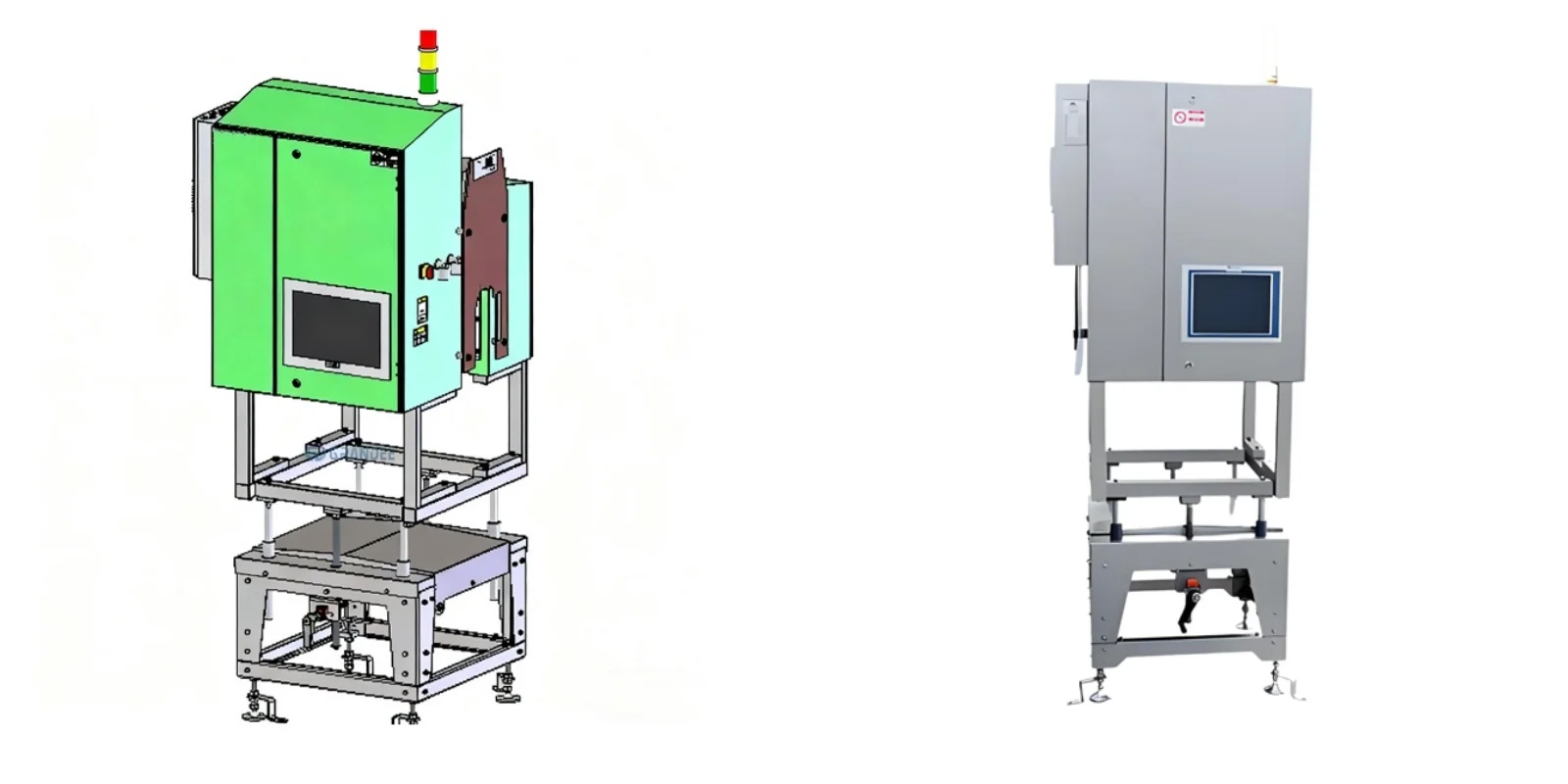

✓ Change Over in Minutes - Adapt to different bottles with simple manual adjustment.

✓ Save Valuable Floor Space - Compact design for easy integration.

✓ Operate with Ease - Clear HMI for real-time status and alerts.

✓ Get a Custom Fit - Detection units configured to your exact needs.

Ready to Boost Your Yield?Contact Us for Details!

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM