Introduction to the blowing machine

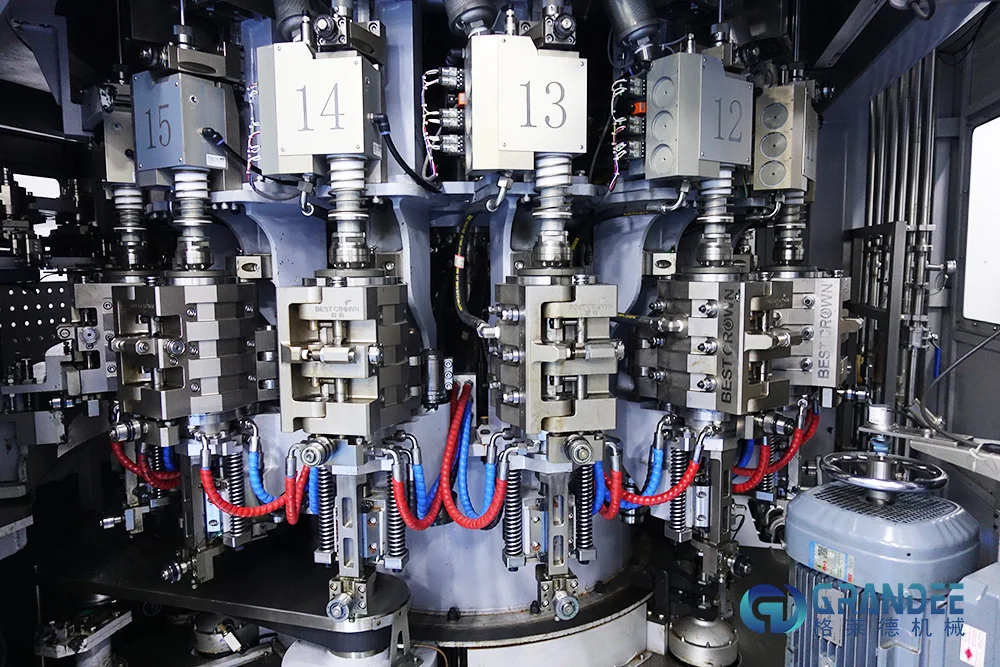

Introduction to the blowing machine The core parts, such as the sealing cylinder of the bottle blowing valve island, are all imported and customized by SEITZ. Blow bottle high pressure gas recovery is applied to low pressure gas needs.The inverted heating furnace structure saves energy by 15%.Bottle blowing has pressure detection and bad bottle rejection functions.The system running status can be monitored remotely. Using forged high-strength mold frames, the equipment operates efficiently and stably. The equipment's running track cam is patented, with low vibration, low noise, and stable and reliable operation!

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM