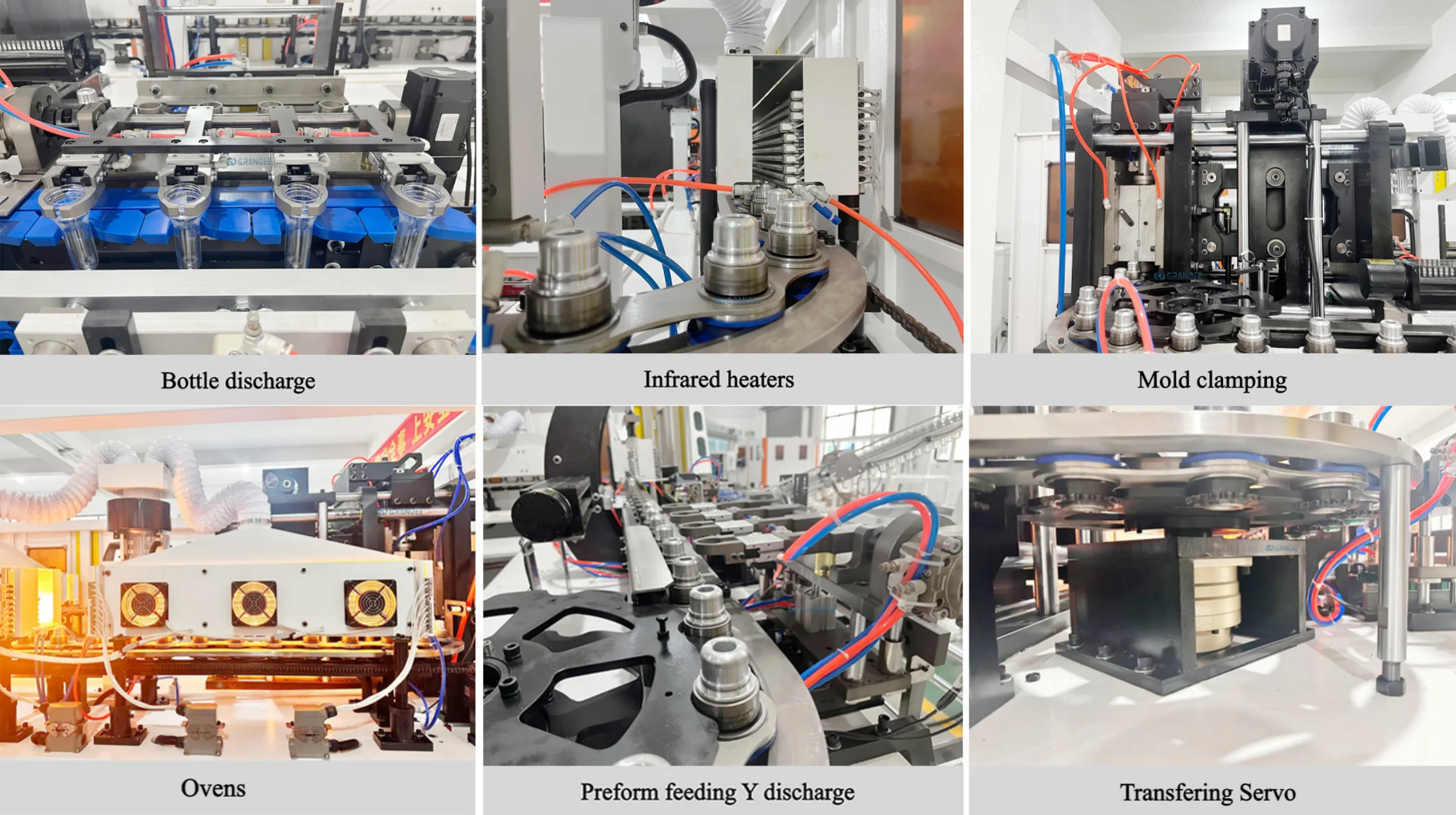

1.Bottle preform fixture, automated conveying, and precise positioning of preforms, preparing for the blowing.

2.

Infrared lamps precisely control heat distribution to ensure preforms can be uniformly blown by high-pressure air in subsequent blow molding processes.3.Shapes bottle profiles with servo-pneumatic systems for precise mold control and automated blow molding

4.Multiple infrared heating elements (visible glowing modules) uniformly and precisely heat PET preforms.

5.Precisely positions and transfers PET preforms with stable orientation for efficient production flow

6.Coordinates molds, servo drives, and pneumatic systems to transform preforms into PET bottles

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM