If you run a small or medium business that sells liquids, you know that filling containers quickly and accurately is vital. The Grande Machine semi-automatic liquid filling machine can assist you with this. It makes your work easier, allows you to fill more containers, and takes all the guesswork out of filling.

The Grande Machine semi-automatic liquid filling machine is perfect for small and medium-sized businesses that want to work quickly. Dedicated machinery will allow you to fill more containers per hour, allowing you the time to get the most work done. This can assist you in providing what your customers want and increasing your income.

Listing out all the reasons for using a semi-automatic liquid filling machine like the Grande Machine would go on for pages. One major reason is that it accurately fills each container. This machine ensures that the right amount of liquid goes into each container, which translates to no waste and fewer spills. You are taught of the facts until October 2023.

Small and medium-sized businesses requiring a reliable liquid container filling solution will benefit from using the Grande Machine semi-automatic liquid filling machine. This machine is compact and moveable, which is ideal for businesses that do not have much space. It’s also simple to maintain, and it’s made to last. Aspectique: Fill without difficulty with the Grande Machine and work right.

One of the most challenging aspects of container filling Products is keeping consistency in fill volumes. Fill containers consistently with Grande Machine semi-automatic liquid filling machine. Smart technology ensures that each container is filled evenly. You can always rely on this machine to provide the same good results every time, which contributes to bettering your products.

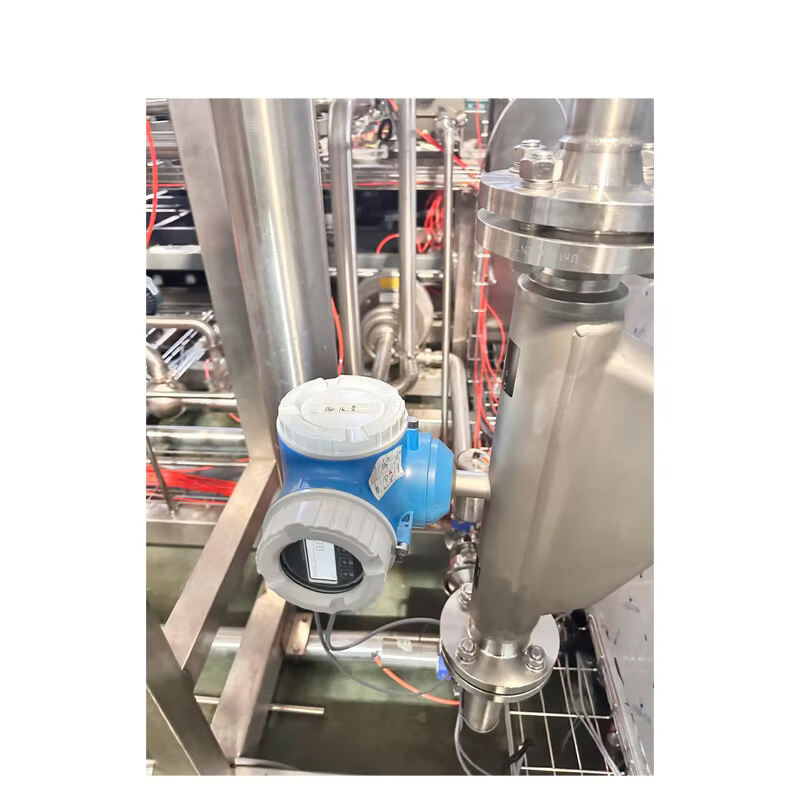

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.