There are many major components that work together to fill bottles on a bottling line. These include a conveyor belt, a filling machine, a capping machine, and a labeling machine. The conveyor belt transports the bottles along the line. This is the machine stuffing the bottles with the beverage. The capping machine places a cap on the bottle, and the labeling machine places a label on the outside. Each of these components works together to make certain that the bottles are filled correctly and ready to be delivered to stores.

A bottle is put through a sequence of steps on bottling line equipment to ensure that it is properly filled and sealed. First, the bottle travels along a conveyor belt to the filling machine. The filling machine fills the drink into the bottlip until it is full. Then the bottle goes to the capping machine, which applies a cap on top to seal it. Finally, the bottle is sent to the labeling machine, which attaches a label so readers know what drink is inside. The bottle is corked, labeled, packed and sent to the stores for people to purchase and consume.

Bottling Line Equipment Bottling line equipment is a critical part of the bottling process as it ensures that the beverages are accurately filled and properly sealed. Without this equipment, putting drinks into bottles would be a significantly harder and slower process. Seal the beverages tightly with this equipment to make it safe for human consumption. It saves time and money for beverage manufacturers because it’s able to fill and seal bottles more quickly than by hand.

Bottling line equipment enables companies to create more drinks within a shorter amount of time. As the equipment can fill and seal bottles both quickly and accurately, businesses can create more drinks in a day than they could if doing it by hand. This helps companies meet demand for their drinks and get them into stores more quickly. Internal B2B Processes & Efficiencies: Though not as fun sounding as external benefits, instrumental to your bottling line project success are the internal processes and efficiencies that a new bottling line equest can bring about.

There are a few reminders to consider when choosing a bottling line equipment for your business. To start, think about how large your company is and how many drinks you a day to fill. This will guide your decisions on how big and fast of the bottling line equipment you'll need. You should also consider the kinds of drinks you are putting into them and any special needs they have. For instance, some beverages may have to be filled at a specific temperature. Finally, Validate that you have a trusted company, for instance, GRANDEE MACHINE, to give the best bottling line equipment up to the quality that ensures the success of your company.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

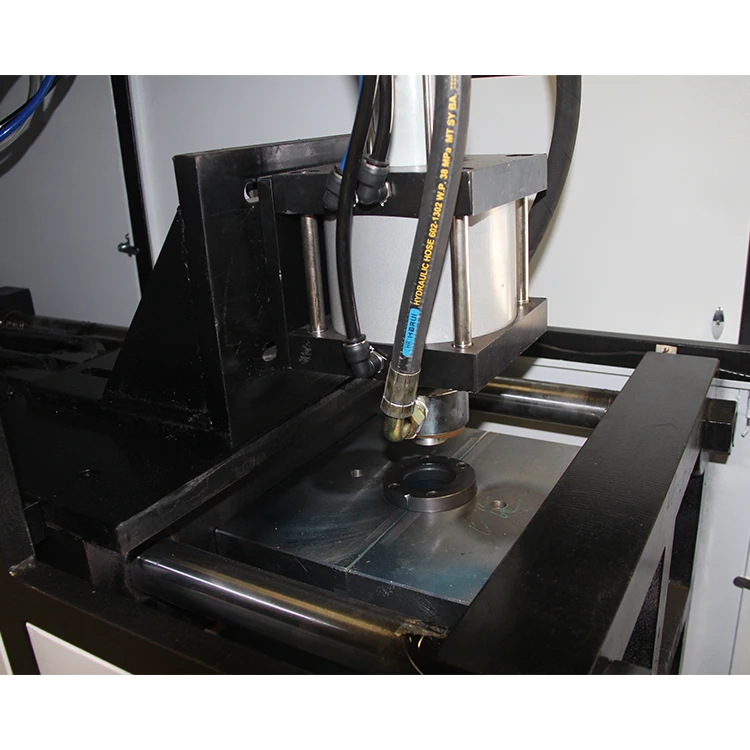

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.