Automated labeling machines are used by many companies to improve the efficiency of their operation, and GRANDEE MACHINE is no exception. These mineral water filling machine avail labels to products at a very high speed and accuracy. This saves time and requires fewer workers to apply labels by hand. That means companies can produce more products in less time, and that makes them more money.

One of the greatest advantages of these machines is that they aid in making labeling more efficient and precise per unit. The machines place the purified water reverse osmosis system labels precisely where they need to go, which results in fewer errors than when people do it by hand. As a result, the products are always labeled correctly, which makes it possible for the company to maintain a positive quality and makes customers happy as well.

There carbonated filling machine are many advantages of using automated labeling machines for businesses. They make work easier and save money over time. Since less employees are required, employers can save more on labor and use that income in other essential items. Additionally, using these machines reduces waste, as they apply labels correctly the first time, meaning that there is no need to fix mistakes.

Understanding what products are is extremely important for businesses. These informative labels can be put on products using automated labeling machines. This mineral water bottling machine helps companies track their products and confirm they are delivered to the correct customers. It helps companies like GRANDEE MACHINE gain customers' trust and build a good reputation.

For companies like GRANDEE MACHINE, automated labeling machines are revolutionizing their product packaging. These machines, which operate at high speed and high precision, help firms pack products quicker and better by quickly and correctly labeling them. That soda bottling machine makes it easier for them to meet what customers want and even to take on new chances to sell. This will help in doing better than the competitors and growing with these machines.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.

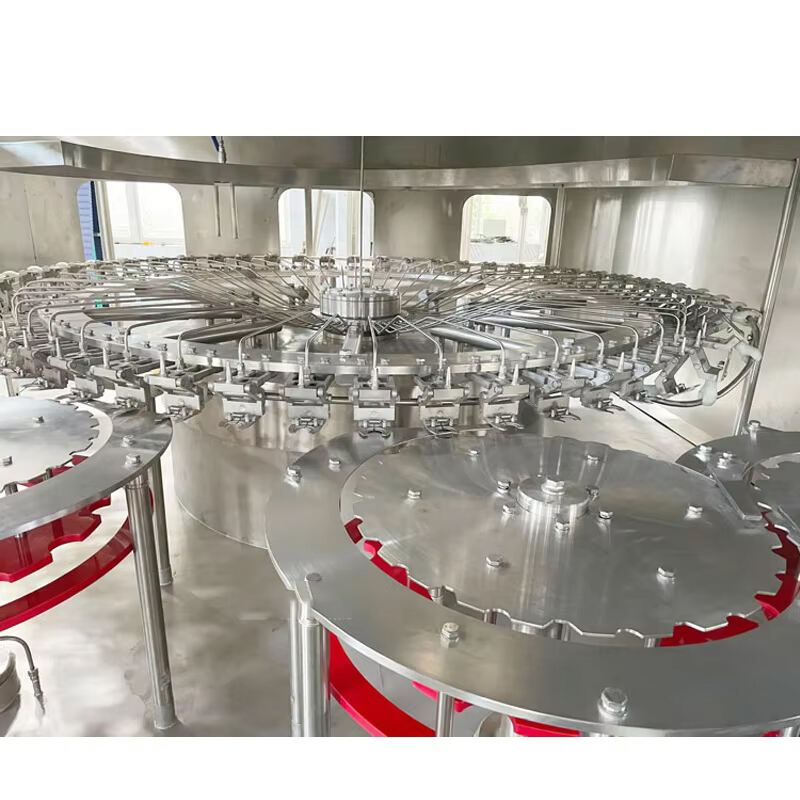

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.