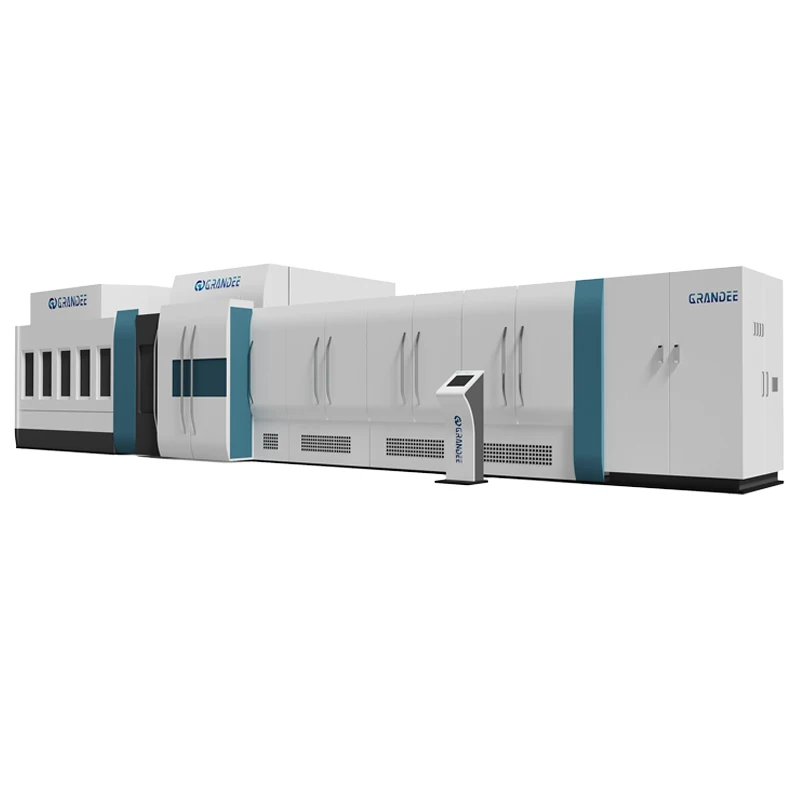

Introduction to the blowing machine The core parts, such as the sealing cylinder of the bottle blowing valve island, are all imported and customized by SEITZ. Blow bottle high pressure gas recovery is applied to low pressure gas needs.The inverted heating furnace structure saves energy by 15%.Bottle blowing has pressure detection and bad bottle rejection functions.The system running status can be monitored remotely. Using forged high-strength mold frames, the equipment operates efficiently and stably. The equipment's running track cam is patented, with low vibration, low noise, and stable and reliable operation! Automatic blow molding machine mold The mold is an important factor affecting the PET bottle blow molding process, and the shape of the mold will reduce or increase the difficulty of process adjustment. For example, the reinforcement, the arc of the transition zone and the heat dissipation condition at the bottom have an impact on the process adjustment and directly affect the quality of the bottle, so we recommend that customers pay attention to the novel and unique product packaging and beautiful at the same time, take into account whether the selected bottle type can meet the requirements of use, it is best to be reviewed by our professional designers. When the mold is customized, it is mainly necessary to clarify the material and installation size. Make product capacity height requirements.

EN

EN

AR

AR CS

CS DA

DA NL

NL FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RU

RU ES

ES TL

TL ID

ID SK

SK VI

VI SQ

SQ TH

TH TR

TR MS

MS GA

GA MK

MK HY

HY AZ

AZ KA

KA HT

HT LO

LO LA

LA MN

MN NE

NE SO

SO MY

MY KK

KK UZ

UZ KY

KY SM

SM