Water filling machines are one of the most significant machines used in bottling plants. They facilitate the speedy packaging of water so it can be shipped out to grocery stores. These GRANDEE MACHINE water bottle packing machine fill and seal bottles of water, preparing them for sale. Easy to use water packing machines at GRANDEE MACHINE!

Using a water packing machine from GRANDEE MACHINE can enable bottling plants to speed up their workflow. Bottled water filtration is also a quick process using a machine that fills and seals a bottle, which allows them to produce more bottled water in less time. It saves both time and money for the companies.

Thus, a water packing machine can increase efficiency and reduce bottling plant costs. The machine itself does the work of filling and sealing bottles. This allows for faster production and makes it cheaper for workers. GRANDEE MACHINE mineral water bottle packing machine can be easily operated and require very little assistance and therefore make a good choice for bottling plants.

GRANDEE MACHINE water packing machines create premium packages. They fill and seal the bottles nicely and ensure the products are safe. GRANDEE MACHINE mineral water packing machine enables companies to provide customers great bottled water, hence making them believe in their brand.

Bottling plants can provide the people with clean bottled water in the safe bottle using a GRANDEE MACHINE plastic bottle packing machine. The water is in this machine and kept pure while packaging, so the final product is of very high quality. It implies that clients could drink water with assurance that it is safe and reviving.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

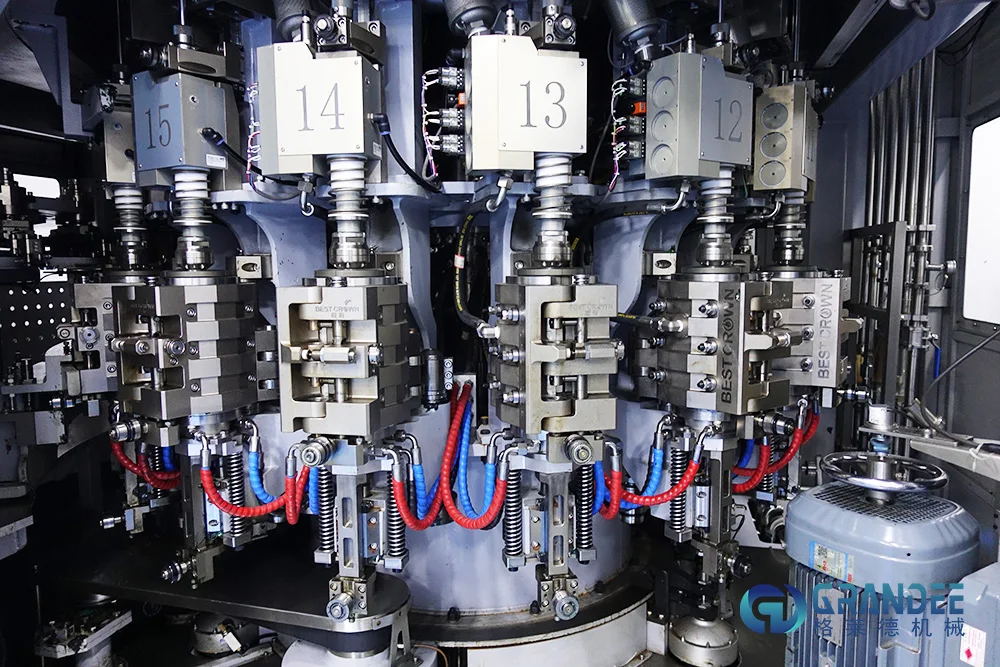

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.