When you reach in and grab a bottle of your favorite drink at the store, do you ever wonder how it came to be? The tasty drinks we love to have every day are made with beverage machines. Let’s find out more about the workings of these GRANDEE MACHINE beverage filling equipment and how they enable businesses to bring delicious beverages to us.

So beverage machines is a magic kitchen that prepares a delicious drink by mixing and stirring ingredients. You follow a recipe to bake cookies, so do these machines follow a recipe to create drinks. Mixers machine mix the combination of water, sugar, and flavours to prepare the drink. Other machines, such as fillers and cappers, assist with getting the drink into bottles and sealing them tightly so they don’t go bad.

However with new inventions and clever ideas drink transition is getting faster and more creative. Companies like GRANDEE MACHINE, which continuously seek better ways to developing drinks. They might also develop a new filling machine that can fill bottles twice as quickly, for instance. These novel ideas enable companies to produce more drinks in a shorter time frame, so that you can have your favorite drink easily available on store shelves.

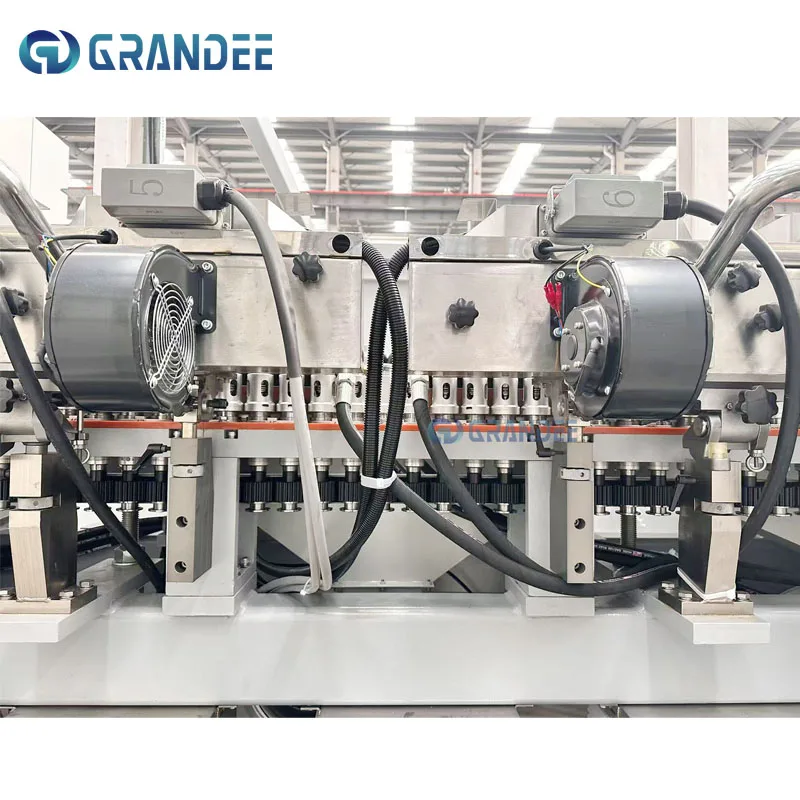

Efficiency is a broad term which you can explain it doing thing timely and effortlessly. It has beverage machines that save companies time by doing things that would take a long time if done by hand. GRANDEE MACHINE carbonated beverage filling machine do a lot of work mixing ingredients, filling bottles and packaging drinks much faster than human beings can. So, companies can produce a lot of beverages without necessarily requiring a massive workforce.

With the improvement of technology, the future of drink-making looks brighter than ever. GRANDEE MACHINE Beverage Mixing Tank allows companies to create more notebook flavors more simply as machines will be increasingly smart. There are probably more machines you will see in your future that will be able to mix together the ingredients in ways we can’t even think of or fill the bottles to the perfect margin every time. With all this, the companies such as GRANDEE MACHINE are thriving to build the new technologies for the drink industry.

Ever wonder what it’s like inside a beverage machine factory? Picture a bustling space filled with machines whirring and grinding as they go. Workers monitor the machines closely to ensure everything is running smoothly. GRANDEE MACHINE beverage filling machine may adjust settings, troubleshoot or simply gawk as bottles travel along conveyor belts to be packed in boxes and shipped to stores.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.