Are you looking to make your production line more efficient and effective? GRANDEE MACHINE auto liquid filling machine is the solution you seek! This amazing device allows you to fill containers with a liquid fluid quickly. Continue reading to discover more reasons you should consider an auto liquid filling machine for your production line.

Imagine filling bottles and containers with liquid and not doing it with your hands. That’s the role of an auto liquid filling machine! This machine fills the containers with liquid which will save you time and energy. With GRANDEE MACHINE auto liquid filling machine to fill more containers and waste less. Plus, you'll spend less time on mere maintenance and more on other critical jobs in your production line High speed linear sticky labeling machine

Considerations When Choosing the right auto liquid filling machine For You First question — what size are your containers and how much liquid will you be putting in them? Ensure the size and quantity of your containers can be accommodated by the machine. Then, see how fast and accurate the machine is. You need a machine that fills containers at the right speed and the right level to meet demand. And finally, features that ease your work, such as automatic bottle positioning and filling level adjustment.

Fill Zips/Spouts vs Regular Pour Spouts Are you sick and tired of filling bottles/containers by hand, for hours? An automatic liquid filling machine can help you to make your bottling process hassle-free while saving you both time and energy. This machine quickly and accurately fills containers with liquid, allowing you to focus on other tasks. And the machine is user-friendly, so you’ll be set up and ready to go quickly!

Using an auto liquid filling machine has many advantages and one of them is that it increases your speed and accuracy. This machine will help you fill containers with liquid a lot faster than manually. It ensures containers are filled accurately every time, eliminating waste and getting you more done. GRANDEE MACHINE'S automatic liquid filling machine will help to get rid of spills and mistakes.

Using an ERP system, we systematically manage production, achieve rapid development output, and facilitate the swift market entry of customer products.

We possess 90% self-produced products, allowing us to control costs from the source. Most of our customers are from South America, Central Asia, Africa and Southeast Asia, etc. We have over 15 years of experience in the production.

We prioritize APQP for quality and standardized process management. We have 80 inspection devices for comprehensive testing from raw materials to finished products, ensuring product performance and environmental compliance.

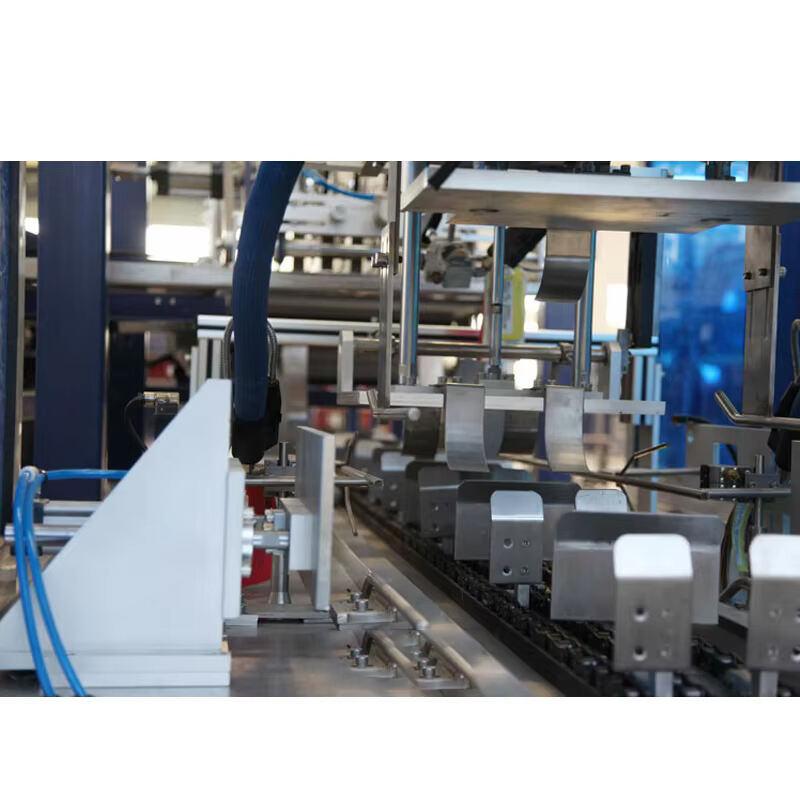

The 1500㎡manufacturing base features 100 automatic beverage filling production lines, including injection molding machines, blow molding machine, water treatment machine, beverage filling machine, labeling machine, packing machine and 500+ other devices, ensuring reliable production capacity. We offer ODM and OEM customized services.